Product Categories

- FPV Drones

- FPV Battery Charger

- FPV Remote Control

- FPV Screen

- FPV Motor

- UAV Drone

- Cleaning Drone

- Tethered Drone

- Fixed Wing Drone

- Lower the fixed wing

- Drone Mounting

- Fire Nozzle

- Fire Hose

- Fire Bucket

- Dry Power Fire extinguishing tank 10L/20L/30L

- Broken Window fire bomb laucher

- Broken window fire bomb

- 6-way thrower

- Dry powder dire ball

- Dry powder water based fire bomb 15L/25L/50L

- Forest fire extinguishing bomb

- Searchlight

- Light module

- Small load dropping equipment

- Material transport box

- Downcomer

- Fire bomb thrower

- megaphone

- seachlight

- 60mm thrower

- 80mm thrower

- 82-2mm thrower

- 48mm grenade laucher

- Trap net transmitter

- Smock bomb launcher

- High-pressure cleaning kit

- Water intake device

- fire breathing device

- gas detecion equipment

- Water flow meter

- Spraying painting set

- 15kg large load head

- 50kg large load head

- Lidar scaning system

- High-altitude ckeaning kit

- FPV Frame Kits

- FPV Stack

- FPV Camera

- FPV Goggles

- Drone battery

- Lipo Battery

- Lithium-Ion Battery

How They Typically Work

-

Aerial Platform: Multirotor drones (often quadcopters or hexacopters) provide stable flight and precise positioning.

-

Cleaning Mechanism: Varies by application:

-

Contact Cleaning: Uses rotating brushes, wipers, or microfiber pads that physically scrub the surface.

-

Non-Contact Cleaning: Sprays water, detergent, or disinfectant; sometimes uses air blasts.

-

Vacuum/Suction: Some models suck up dust and debris (common for indoor use or specific industrial settings).

-

-

Delivery System: Includes onboard tanks for liquid, pumps, and hoses. The drone must manage weight distribution as fluid empties.

-

Navigation & Control:

-

Manual: Piloted by a human via remote control, often with a live camera feed.

-

Semi-Autonomous: Uses GPS, LiDAR, or visual sensors to follow a pre-defined path or maintain a fixed distance from a surface.

-

Fully Autonomous: Programmed for a specific area, using computer vision to identify dirty spots or avoid obstacles (this is more advanced and less common).

-

Primary Types & Applications

1. Building Facade & Window Cleaning Drones

-

Target: Skyscrapers, high-rise windows, glass structures.

-

How: Use extendable arms with rotating brushes and spray nozzles. They recycle water to minimize runoff.

-

Benefits: Eliminates need for scaffolding, cradles, or rope access (improving safety and reducing setup time).

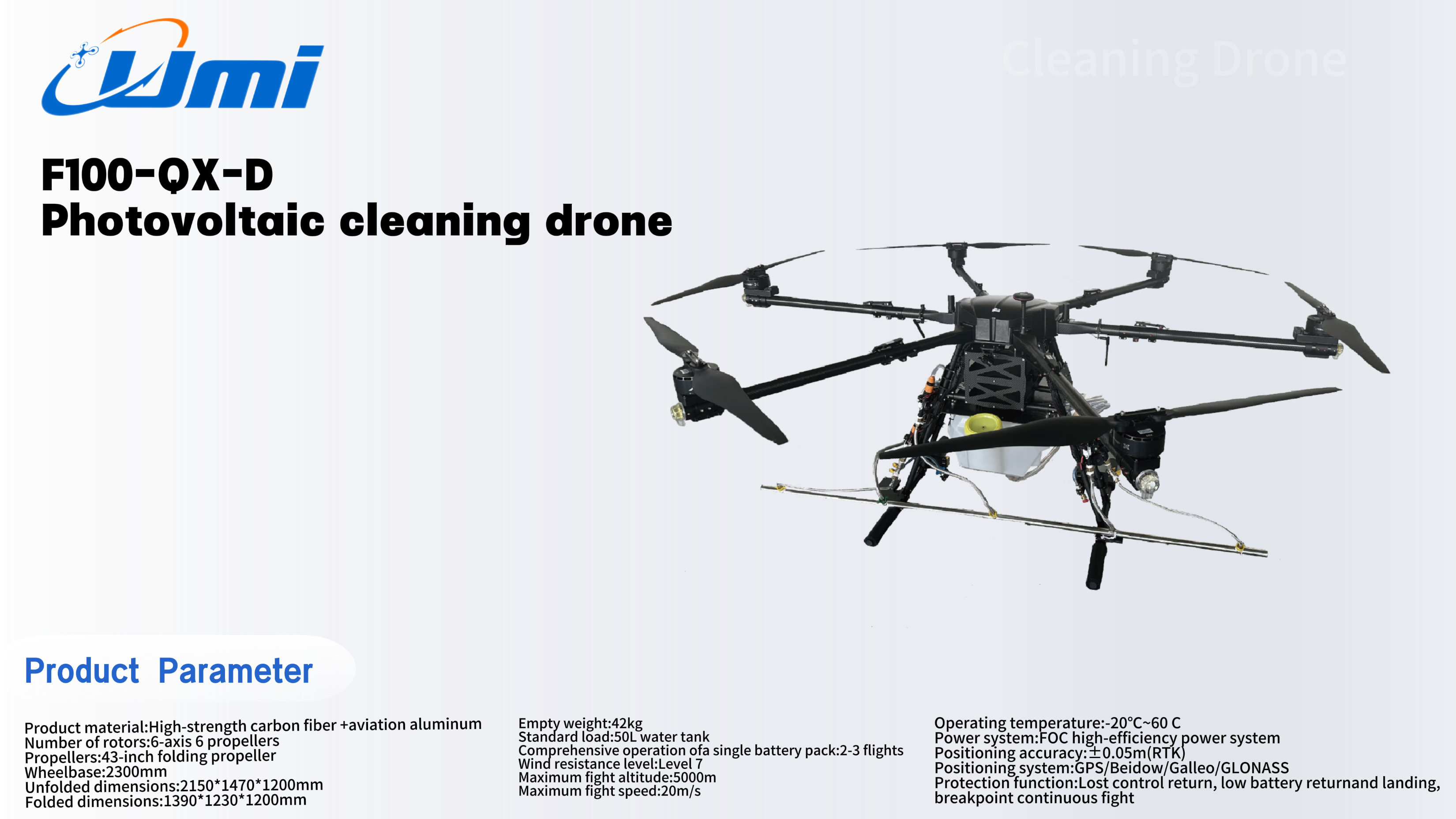

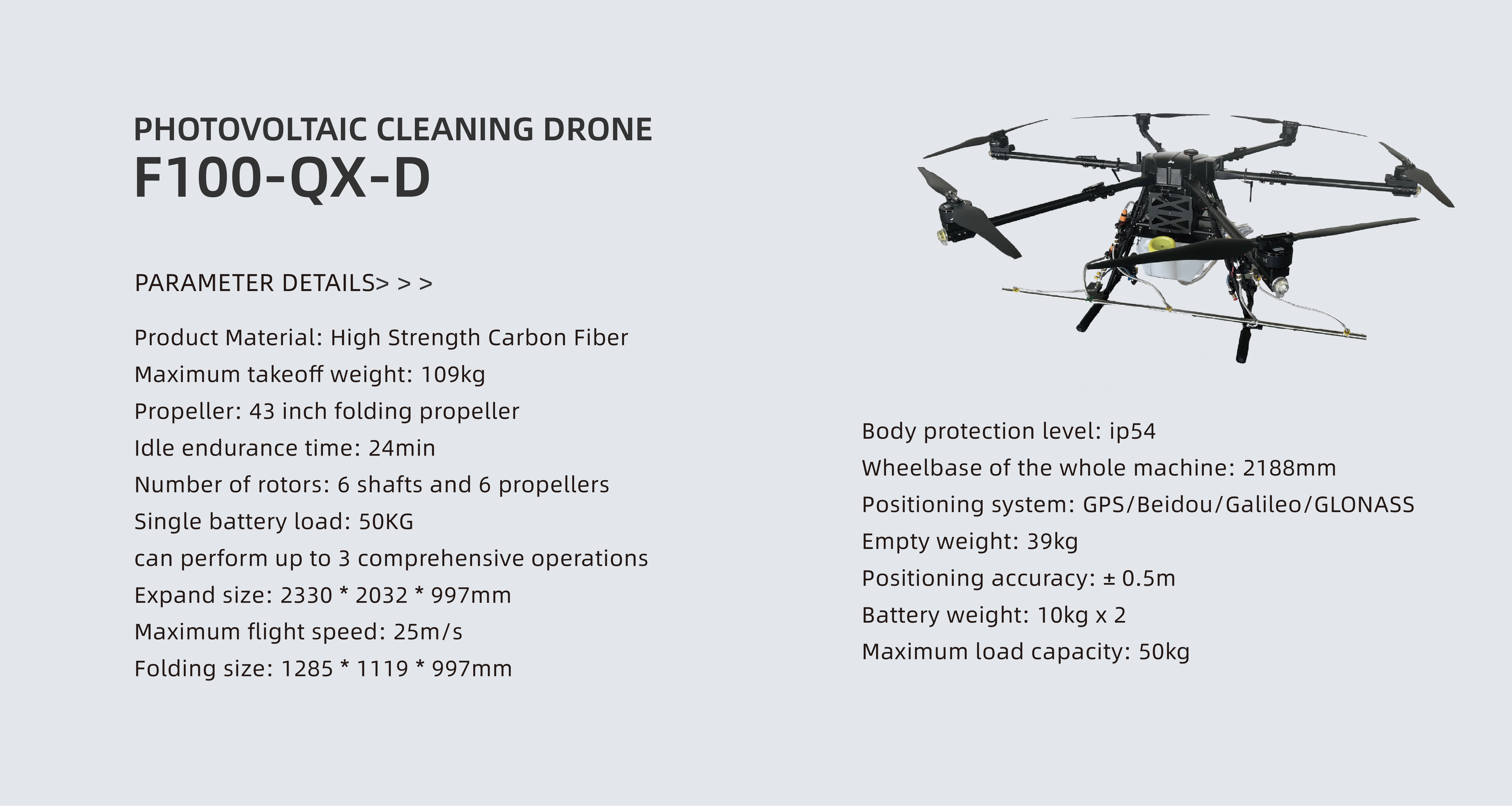

2. Solar Panel Cleaning Drones

-

Target: Large-scale solar farms (especially in dusty regions) and rooftop panels.

-

How: Typically use air-blowing technology (powerful downward air jets to blow dust away without contact) or a combination of soft brushes and light spray.

-

Benefits: Can clean vast arrays much faster than manual crews, with no risk of panel damage from walking on them. Crucial for maintaining energy efficiency.

3. Industrial & Infrastructure Drones

-

Target: Ship hulls, storage tanks, silos, bridges, wind turbine blades.

-

How: Often more robust, using high-pressure water jets or abrasive brushes to remove rust, marine growth, or heavy grime.

-

Benefits: Access confined or hazardous spaces without putting workers at risk.

4. Indoor Cleaning Drones (Less Common/Developmental)

-

Target: Large indoor spaces like airports, warehouses, stadiums.

-

How: Function as flying Roombas, using suction and brushes for floors, or as disinfectant sprayers for high ceilings.

-

Challenge: Indoor GPS-free navigation is complex and safety regulations are stringent.

Advantages

-

Safety: Reduces or eliminates the need for workers at heights or in confined/dangerous spaces.

-

Efficiency & Speed: Can clean large areas (like solar farms) 2-5 times faster than manual methods.

-

Cost-Effectiveness: Lower labor costs and no need for expensive physical access equipment (scaffolding, boom lifts).

-

Accessibility: Can reach areas that are otherwise extremely difficult or impossible for humans.

-

Water Conservation: Many systems are closed-loop, recycling up to 80-90% of the water used.

Challenges & Limitations

-

Flight Time & Payload: The biggest constraint. Battery life is typically 15-30 minutes. Carrying heavy water/cleaning fluid limits operational time.

-

Weather Dependence: Wind, rain, and temperature extremes can ground flights.

-

Precision & Damage Risk: Incorrect programming or a sensor failure could cause the drone to collide with and damage the surface it's cleaning.

-

Regulation: Operating large drones, especially near people or urban areas, requires permits and adherence to strict aviation rules.

-

Initial Investment: High-quality industrial cleaning drones are expensive ($10,000 to $50,000+).

-

Surface Variability: A drone programmed for flat glass may struggle with curved or highly textured surfaces.

The Future & Key Players

-

Technology Trends: Longer battery life (hybrid fuel cells), better AI for autonomous dirt detection, swarming technology for multiple drones to work together, and advanced sensing (ultrasonic, LiDAR) for perfect surface following.

-

Leading Companies: Companies like Aerones (heavy industrial), Solaire (solar cleaning), Skypick (indoor logistics/cleaning), and Ecocopter are pioneers. Many traditional drone companies (DJI) provide platforms that can be customized for cleaning.